.png?v=v1)

.png?v=v1)

The key project "Dongben Integration" in Guangdong Province invested and constructed by Dongfeng Honda Auto Parts Co., Ltd. will be completed in Dayawan District, Huizhou. With a total investment of 4.5 billion yuan, the project will build 1.5 to 2 million complete vehicle parts and components, covering an area of 420,000 square meters.

With the core values of helping customers create value, sharing value with employees, and dedicating value to the society, Jiangsu Sfere Electric Co., Ltd. and Dongfeng Honda jointly assist smart factories and accelerate transformation and upgrading.

Sfere Electric relies on a modern management system, with advanced process equipment as a guarantee, uses an efficient information management system, and provides customers with the most valuable cooperation platform with excellent research and development, high-quality products and perfect services.

At present, the third phase of Dongfeng Honda Company has been launched, with the goal of completing the overall relocation in September 2019. By then, Dongfeng will be fully built into a modern green project integrating "casting, forging and machining" with an annual production capacity of 2 million vehicles. Sfere Electric customized a set of stable, reliable and technologically advanced power monitoring system for Dongfeng Honda, and integrated smart meters, electrical fire monitoring and intelligent control devices in the smart factory to ensure the smooth operation of the project.

In the new factory of "Dongben Integration", Sfere Electric's intelligent power monitoring system and electrical fire monitoring system are used.

Intelligent power monitoring system and electrical fire monitoring system are relatively independent systems with their own independent hardware and operating software. They can also upload data to the superior management platform through network connection to realize data sharing.

Products helped by Sfere

Software and hardware equipment included in the intelligent power monitoring system; Software and hardware equipment included in the power monitoring system; the software and hardware equipment included in the electrical fire monitoring system, and completes the connection, installation and debugging of the monitoring equipment.

Project configuration

In the design of the drawing, the multi-functional power meter PD194Z-9HY and integrated protector are configured on the circuit of the distribution cabinet in each distribution room where the power monitoring instrument is required to be installed, so as to monitor the current and voltage of a single circuit in real time, and then connect to the communication management machine in each distribution room.

After the completion of the system, the communication management machine of each distribution room is pulled to the main control room of the main building through optical fiber through photoelectric converter, and all monitoring data is transmitted to the background of the power monitoring system.

Other equipments with digital communication interface, such as temperature control equipment of transformer, DC equipment, analog screen, etc., need to upload data to background computer for remote monitoring or control.

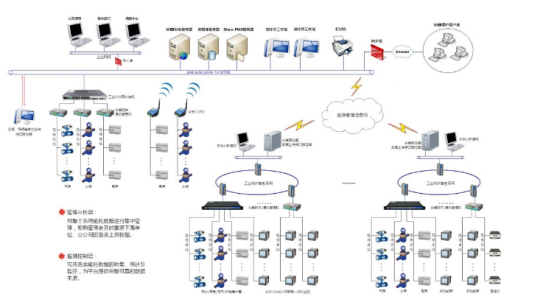

Network topology diagram

The whole network acquisition structure of the system is to communicate with the main control room through the fiber TP/IP network in each distribution room, to complete the centralized data collection and processing. The network is divided into upper layer network and bottom network. The upper layer network is the Ethernet (or optical fiber Ethernet) from each sub-station to the control center. Industrial-grade optical fiber transceivers are used for photoelectric conversion between the optical fiber and each management device.

The bottom network is the RS485 communication cable between instruments, protection and other equipment, which is laid with dedicated twisted pair. Since the communication management machine is configured in their respective sub-stations, the RS485 transmission distance is all within the sub-station, so there will be no long-distance signal interference and attenuation. The equipment layer on the network site mainly includes measuring instruments and protection devices, which are installed in corresponding switch cabinets locally, and have local operation function and are not affected by the start and stop of remote computer. The system consists of three layers from the bottom to top: equipment terminal layer, network communication layer and system management layer.

Implementation function

It can automatically collect and intelligently manage the electric energy information of all kinds of metering points in the high-voltage distribution room and low-voltage distribution room of the whole plant, so that the distribution network can operate in the best state of safety, reliability, high quality and high efficiency; realize the remote measurement, control and management of distribution network, realize the demand of power safety, power management, energy saving and consumption reduction.

By monitoring the residual current, load current and other parameters in the circuit, it can realize the alarm and monitoring of the protected electrical circuit, and upload it to the fire monitoring system to realize centralized control and centralized management. When the relevant parameters in the circuit are abnormal, the monitoring equipment will send out an audible and visual alarm to indicate the alarm position. At the same time, the on-site detector will send out an audible and visual alarm and control signal to remind the user to check or replace the hidden circuit, so as to reduce the risk of fire caused by electrical reasons.

Taking comprehensive electrical application as the development center, Sfere Electric will become a top electrical application solution expert. It is the vision of the enterprise to better serve China's intelligent factory and fulfill the social responsibilities.

Copyright © 2019.Company Name All Rights Reserved.