.png?v=v1)

.png?v=v1)

1. Enterprise introduction

Lanzhou New Area Shuangliang Thermal Power Co., Ltd. was established on July 31, 2013 and was wholly-owned by Gansu Shuangliang. According to the special heat supply plan of Lanzhou New Area, the company is responsible for the construction and operation management of the central heating project in the south of Wei No. 16 Road in Lanzhou New Area. The construction and operation of this project can maximally limit the enterprises that gradually settled down to establish scattered coal-fired small boiler rooms, so as to reduce the environmental pollution to the urban area, improve the environmental sanitation, improve the air quality in winter, improve the heating quality, and realize the utilization of low-quality fuel and garbage.

2. Existing problems

The heating station of Shuangliang Thermal Power in Lanzhou New Area is mainly supplied by three 10 / 0.4 kV transformers. The low voltage side of the transformer is divided into two branches of power and lighting, with active and reactive power metering devices respectively. The water pumps, fans and other equipment of the heating station are equipped with multiple low-voltage three-phase asynchronous motors, and the power factor is often about 0.7, which makes the power loss of the power branch line very large. And the power factor is lower than the evaluation standard of the electric power department (0.9).

3. Reactive power compensation design

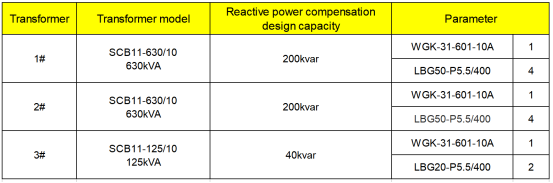

According to the load type and transformer capacity, the design capacity configuration of reactive power compensation between the incoming cabinet and the load is as follows:

3.1 Product introduction

LBG series harmonic elimination reactive power compensation is a kind of reactive power compensation product which aims at the harmonic and power factor problems in the 0.4KV low-voltage distribution network where harmonic pollution is serious. It can improve the power factor, effectively suppress the harmonic, reduce the line loss and improve the power quality.

The harmonic elimination reactive power compensation components include: filter reactor and low voltage filter power capacitor to form a filter compensation circuit. This series of components is a filter compensation equipment suitable for 0.4kV low-voltage power distribution network. The series of compensation devices have complete protection measures and high degree of automation. They can automatically quit the work when the external power fails, and automatically resume operation after power is supplied.

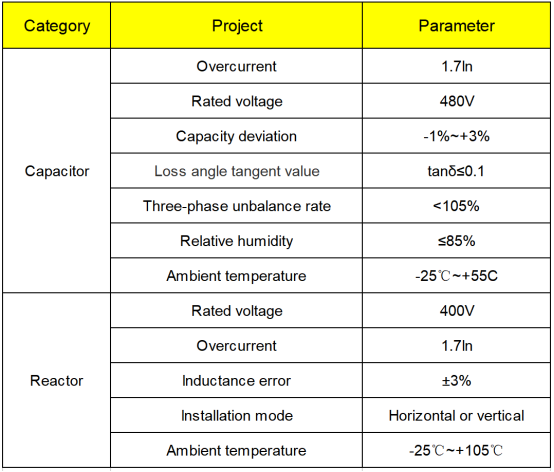

Technical Parameters

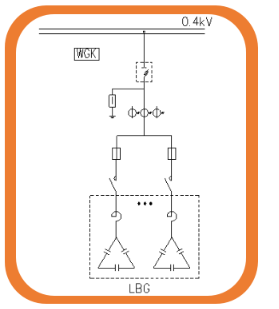

3.2 Design Diagram

4. Project Summary

The expected goal is achieved. The power factor of each transformer's incoming cabinet is increased to 0.98. The power consumption of the enterprise meets the reward requirements of the power supply department, which brings actual economic benefits to the enterprise. At the same time, installing reactive power compensation device in the heating system can not only improve the power factor, save the active power, reduce line loss and transformer loss, reduce operating costs, but also improve the load capacity of the power supply and distribution equipment in the boiler room, reduce the investment cost of the new boiler house, reduce the voltage loss, improve the operation conditions, and make it easier to start the circulation pump and the induced draft motor of the heating station.

With the rapid development of China's economy, the contradiction between supply and demand has become increasingly prominent, and people's awareness of energy conservation is also constantly improving. The heating industry should also actively carry out technical transformation, reduce production costs, save energy and better serve the people.

Copyright © 2019.Company Name All Rights Reserved.