.png?v=v1)

.png?v=v1)

1. Project overview

The Hami Power Plant 4×660MW project is one of the first supporting power sources for the Hami-Zhengzhou ±800 kV UHV DC transmission and distribution project. The project adopts the construction mode of coal-electric power integrated pit-mouth power plant. Coal is directly transported into the plant by belt, which can realize the on-site conversion of resources and convert coal to electricity, which is in line with the national energy industry policy.At the same time, the construction of this project can connect Xinjiang, which accounts for one-sixth of the country's total area, to the Northwest Power Grid, which can realize the real national power grid and the optimization of resources in a wider range.

2. Overview of operating conditions

The direct air cooling system of the 3# and 4# units of the Hami power plant 4×660MW project, each set of direct air condenser system (ACC) is composed of 8 rows, 8 fan units per row (1 fan per fan unit), There are 64 fan units in total, and each fan is controlled by a frequency converter to adjust the fan speed so that the exhaust pressure of the steam turbine is controlled at the set value. As a typical non-linear load, the inverter generates high-order harmonic currents during operation, which leads to excessive voltage and current in the power supply system, which deteriorates the power quality and seriously affects the reliability and stability of the system.

In order to improve the use efficiency of factory power supply, reduce the non-application capacity of the power supply, and effectively eliminate the long-term harmonic pollution caused by the inverter, choose SFRPF series active power filter to filter the harmonics generated by the inverter during operation Voltage and harmonic current.

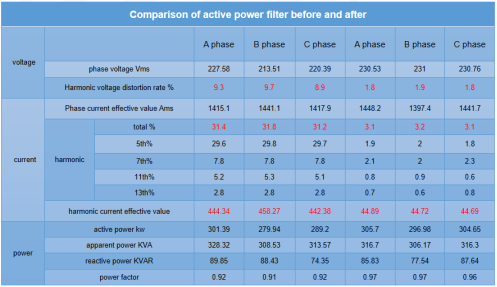

3. Data measuring

Comparison of grid harmonic data before and after the active power filter is put into operation:

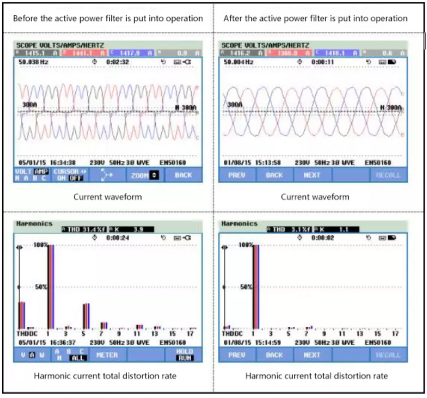

4. Waveform diagram

Waveform comparison before and after the active power filter is put into operation:

5. Project summary

Realized the expected goal. The harmonic voltage and harmonic current distortion rate of each transformer inlet cabinet reached the requirements of the national standard "GB/T 14549", which purified the power environment and ensured the safe and stable operation of the equipment. The earth improves the effective utilization of electrical energy; reduces the distribution line losses, increases the terminal voltage and extends the service life of cables and equipment.

Copyright © 2019.Company Name All Rights Reserved.