.png?v=v1)

.png?v=v1)

1.Summary

Industry is the major power consuming segment of the national economy, it accounts more than 70% of the entire social power consumption. As the industrialization and urbanization process being accelerated, there is great pressure for the energy saving and emission reduction. The utilization of information technology to build a digital energy management system to achieve the precise energy saving management. It helps the administration bureaus to collect energy consumption and analyze the trend, implemented and flourishing the industrial policy, push forward the transformation and development of the national economy segments.

GB 17167-2006 《General Rules for Equipment and Management of Energy Metering Instruments for Energy Use Units》

GB/T 23331-2012 《Requirements for Energy Management System of Industrial Enterprises》

Power management system, energy management center and energy efficiency construction is the crucial of the energy saving. Push forward the online energy consumption monitoring, it’s not only the requirement of the high efficiency of the energy saving from the government but also the internal request of the district energy consuming trend.

The main work of the construction of the power management center is to use the energy consuming data such as electricity, raw coal, natural gas, oil, water and the steam or heat power which transform from the above mentioned energy to monitor, record, analyze and solve the problems. The online real time monitoring of the energy consuming status provides the objective materials for the energy user to figure out their weakness for the power consumption, enhance the power management level and reduce the production cost as well. It helps the enterprises to flourishing the appraisal of energy efficient equipment by monitoring and analyzing the data, reduce waste of energy. It also helps the enterprise to reduce the unit energy consumption cost and the maintenance cost enhance the competitiveness. It provides a new concept for the company operation management, metering management, power management as well.

Meanwhile enterprises could strengthen the power consumption management by connecting with the government energy management platform to the industrial energy management. Utilized the technological and environmental methods to reduce the energy consumption, decrease the waste materials emission and let the energy consumption in a high efficient rate.

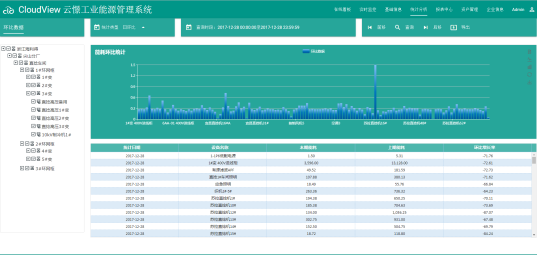

The device and the user could connect to the intelligent industrial energy management platform by Internet. User could create their own account according to the projects respectively, those projects could running on this platform simultaneously. But the pages and data could be distinct by the independent account or projects, provides an exclusive experience to the user. Or install the whole cloudview platform to the server cluster of the home-make monitoring center , or rent a server cluster in the public data center.

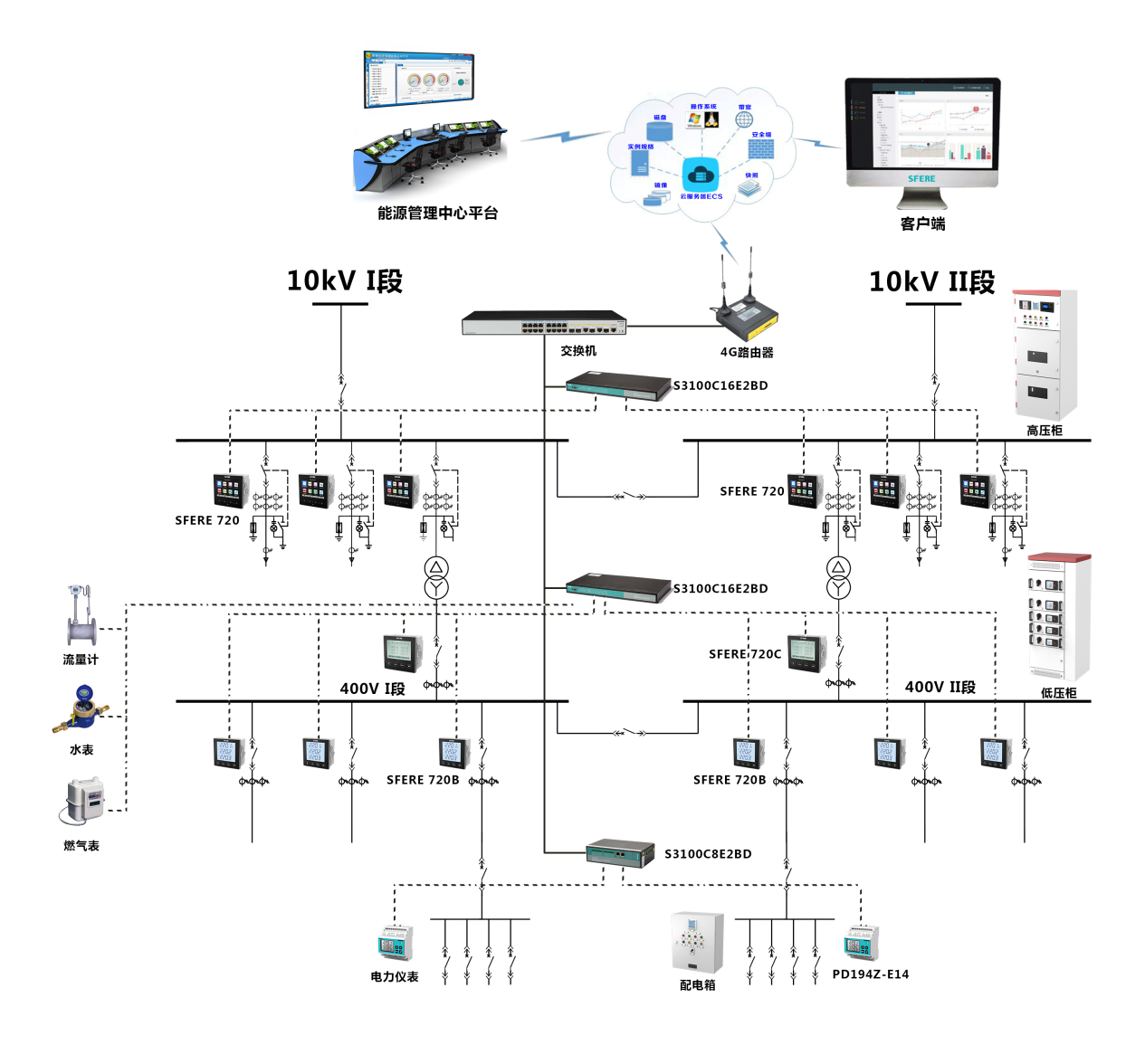

The cloudview platform support the worksite bus, Elthernet, wireless 3G/4G multi-networking solutions, generally it could categorized as measuring and monitoring instruments, network communication devices, Cloud processing center and the running ended for sections.

The Cloud computing center is the core of the Cloudview platform including the collection server, data base server and the Web display server. It could be allocated at the private or public cloud, it could also allocate at the local server as well.

Business running ended is the operating ended of the Cloudview ended. It could browse the web by the internet or by LAN. It also support the APP browse by mobile phone to working anywhere any time.

Network devices including the communication management machine, exchange machine which for the data collection, data cache, positive data uploading, LAN, publish internet, 3G/4G and GPRS wireless data transportation.

the selection of the meter and monitoring instruments and the data loggers which install at the power distribution cabinets. According to the requirement of different projects, the meter size and the type of installation should be as following:

For those new construction projects, the Sfere 720, Sfere 100, PD19 series panel mount meters would be a very good choice. Those meters have the RS485 COMM interface, it could be networking at the worksite and upload the measuring data to the Cloud.

For the industrial reconstruction cases, normally the devices were old, or were analog meters even none of them but request for the intelligent reconstruction. The device must have RS485 interface for the networking function. At the previous design stage, the PD194Z-E series, Sfere700 series could be considered. The installation type of these energy meters are din rail mount and multi-loop measuring available.

Application | Model | Main Function |

High voltage loop Low voltage incoming line Bus coupler loop | SFERE720 | ●Total electric parameters measuring ●4 tariffs 12 time interval power measuring ●Up to 63rd harmonic measuring ●Power quality detection, Demand and extremum statistics ●1 loop RS485 interface,Modbus-RTU protocol |

Low voltage feeder Low voltage power substation | SFERE720B | ●Total electric parameter measuring ●4 tariffs 12 time interval power measuring ●Up to 51st harmonic measuring ●Power quality detection, Demand and extremum statistics ●1 loop RS485 interface,Modbus-RTU protocol |

Terminal lighting box power box in low voltage distribution room | PD194Z-E14 | ●1~4 3 phase or 3~12 single phase input ,including voltage, current, power factor, energy metering, harmonic and extremum etc. ●Solid core CT and Split core CT are supported, current range 5A or 100A~600A ●1 loop RS485 interface,Modbus-RTU protocol |

Low voltage power substation Lighting power box | SFERE700 | ●3 phase grid voltage、current、power factor、frequency、power metering、harmonic measuring、extremum statistics ●Solid core CT and Split core CT are supported, current range 5A or 100A~600A ●1 loop RS485 interface,Modbus-RTU protocol |

Data collection and uploading | S3100 series | ●By using the serial port and Elthernet to collect, processing, cache to upload the data to the cloud by LAN, public network through 3G/4G wireless transmission ●2/4/8/16 loops optional RS232/RS485 port ●Achieve the protocol conversion from jobsite to the server, support the IOT protocol MQTT,standard Modbus-RTU/ASCII/TCP、comply with DTL645-1997/2007、IEC101/104 |

Intelligent industrial energy management system is based on the meter measuring, bus bar communication, web technology and the Cloud computing, combines the enterprise function and productivity, it statistics the energy consumption in different directions, analyzes the unit energy consumption. Improves the energy consuming efficiency and strengthen the competitiveness of the enterprise by computing the energy consumption to production output ratio.

Display layer:the section of between the user and the data exchange platform,it combines由from the web client-side, computer or mobile phone APP,it’s the section for the user to platform which provides display, query and analysis.

Services layer:provides the service bus bar of the platform,including system integration and Plug-in interface, platform service, event motivation service, real time data analysis service etc. Bus bar server supports dynamic loading and horizontal expansion,each service could be working on 1 or multi VM. When the scale of the system is increased, it only needs to increase the number of the server for the horizontal expansion.

Aggregation layer:

Subscribe the collection layer variation data and SOE information to aggressive calculation by bonding the general data model to achieve the data and SOE information save to the time sequence DB. The aggregation layer and the collection layer will achieve the real time data subscribe and release by formation, and provide standard APF integration.

Collection layer: by Communication management machine and software to connect the smart meters and the sensors etc. It supports various communication protocols, electric regulations.

●Any device connection available

It supports various communication protocols and formats, and the data point description and configuration for different devices providers. The system use the communication management machine to input the monitored device, by configuring the protocol data base and devices base to support the devices dynamic input. The monitoring unit of the software is universal but the hardware was different, it provides different interfaces and collection hardware for various uses. ●Enormous input devices

To avoid large number of low effective data polling and gigantic redundant data upload to the platform, the data which collect, processing and report to the form the devices locally, only the variation data and the SOE will be upload to the platform to release the stress. Meanwhile the platform will be aggressed the distributed information Bus separate data request by increasing the information bus to achieve the enormous devices input.

●Multiple user access;

1, supports large scale access by the user, by setting the direction agent and allocation algorithm to distinct various groups, by increase the server agent to allow more users access.

2, Users could access the data and function modules within their limits of authority to enhance the system security and reduce the unnecessary data transmission.

3,Users and tenant could create various projects online, those projects could be operating on the same platform, but the pages and the data should be distinguished by “user/project”, provides the exclusive system experience to the user.

●API integration

By MQTT open type data interface for real time data, SOE alar, control order and configuration alert changing. The third party system and devices could be collect the real time data integration by MQTT by HTTP RESTFUL interface for configuration and history data access.

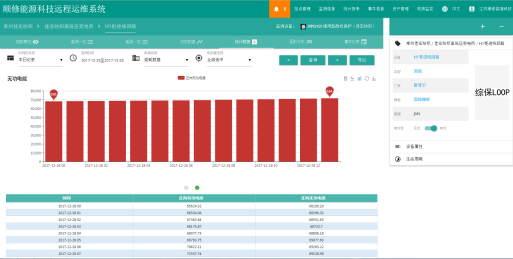

Intelligent industrial energy management platform sources from the leading energy management information technology and concept, it’s the combination of the R & D team, technical experts and clients’ demand of Sfere Electric. By the industrial experience accumulation and the analysis of customer demand for years, the energy management of Sfere Electric becomes safety and reliable to fulfil the requirement of the industrial and commercial customers.

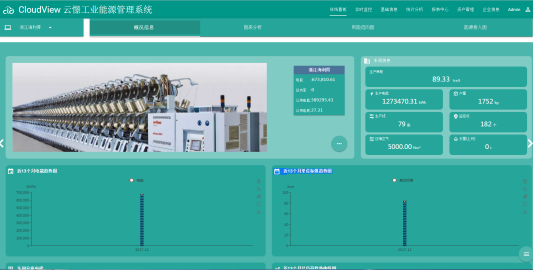

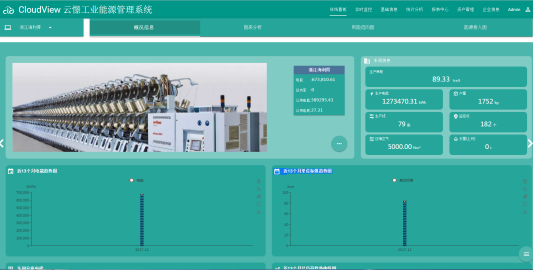

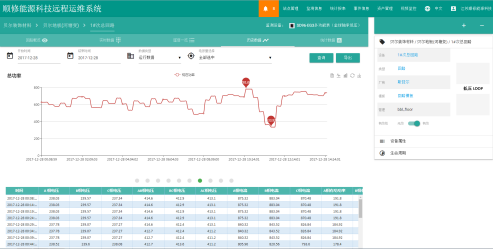

The platform could achieve the energy only Kanban function, display total energy consumption status for the entire enterprise. Take the standard coal unit to convert and analysis, and support the large screen output. Enterprise could display the energy consumption and energy saving effect in real time.

By MQTT subscribe/release new push mode, the platform could processing million pcs data/second to ensure the refreshing frequency of the data page within 15second. Make a large number of devices access as possible and avoid the traditional low efficiency data polling mode.

Specially for the monitoring of the operating status and the parameters(current, voltage, power factor and temperature) to the relevant energy consumption of the production of the production line.

The energy consumption analysis report combines the production line output could analyze the unit energy consumption, energy consume output ratio and those with data in real.

System could calculate the unit energy consumption from the production output quantity and the energy consuming devices of the enterprise, and make the energy performance management by it.

Supported various docking, open for the real time data, SOE information data docking, support electricity demand management platform, data docking with the municipal level of energy management platform

Copyright © 2019.Company Name All Rights Reserved.